-

Electrical Thermal Imaging detects temperature changes in switchboards control panels sockets lights all types of electrical equipment Skegness Lincolnshire

Thermal Imaging

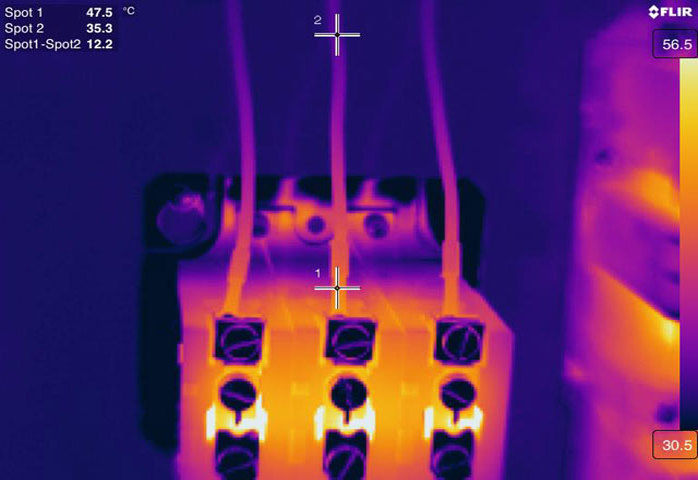

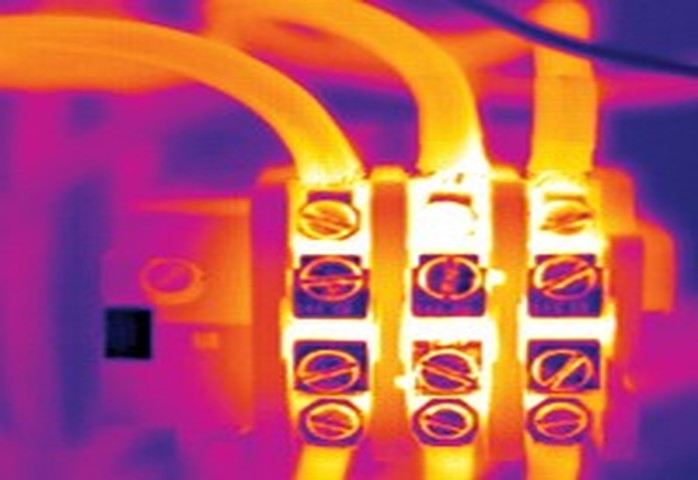

Below overheated terminals

Thermal Imaging

Thermal Imaging

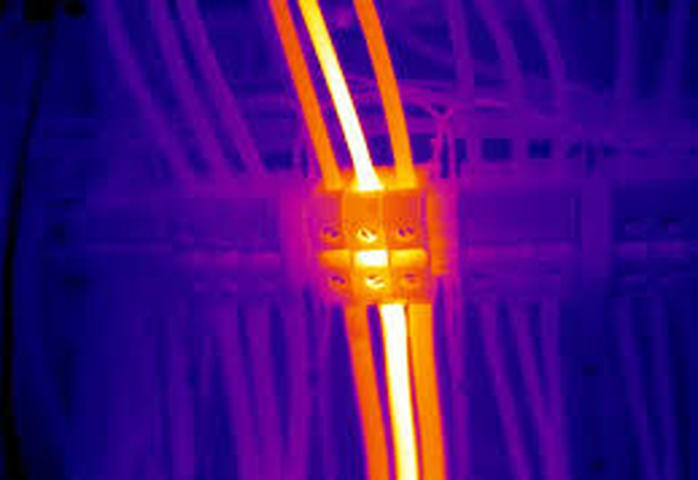

Thermal Imaging is one of the most valuable diagnostic tools for predictive maintenance. By detecting anomalies often invisible to the naked eye, thermography allows corrective action to be taken before costly system failures occur.

Thermal Imaging or Thermography is the process of using a special camera designed to look only for heat by way of infra red (IR) energy waves.

Potential problems can often be found due to excess heat being released by the component, even those which would normally produce some heat when performing at their optimum level.

If undetected these problems can lead to failure and can result in expensive production loss or downtime and, in the most extreme case, can lead to fire.

A regular programme of thermal imaging as part of routine maintenance can highlight potential problems long before any event. As a result any required repairs can be planned for in terms of both time and budget. In short, it is an invaluable resource for predictive maintenance.

Thermography has applications in many different areas which are listed below.

Thermography and Electrical Systems

Loose connections

Overloads

Phase imbalances

Corrosion

High resistance in fuses and switchgear

Thermography and Mechanical SystemsMotor overload

Worn Bearings

Boiler seal leakage

Insulation breakdown

Hydraulic, steam and hot water systems

Tank levels and insulation

Valves

Turbines

Thermography and BuildingsContinuity of insulation

Flat roof leakage

Heating, ventilation and air conditioning

Cold storage thermal gain

Seals

Request a quote now or speak to our team.